Video

Weichai WP7 electronic control engine, whose emission meets the national emission requirements for non-road machinery Phase III, is intelligent and efficient, has strong parts versatility and low maintenance costs; The whole machine is developed and designed according to the working conditions of the mine, realizing the reasonable matching of power, efficiency and energy consumption.

Operating weight

The external gear working device with independent patent technology has large transmission torque and strong resistance to external impact; The blade with a larger angle adjustment range (44°-91°) improves the material control ability and is especially useful when dealing with dry materials and clay, which can significantly improve the operation efficiency of the grader; The connecting rod type swing frame is adopted, which has strong resistance to external impact and is suitable for working conditions with large workload and harsh working environment; Equipped with an overload turbine box, which can realize rotation overload protection and load rotation, and the whole vehicle can adapt to a wider range of working conditions.Parameter

| Engine model | DCEC CUMINS 6BTAA5.9-C150 | |

| Rated power(kw/rpm) | 112/2200 | |

| Travel speed(km/h) | Forward 1 | 0-5.4 |

| Forward 2 | 0-8.3 | |

| Forward 3 | 0-13.2 | |

| Forward 4 | 0-20.6 | |

| Forward 5 | 0-29.6 | |

| Forward 6 | 0-44 | |

| Reverse 1 | 0-5 | |

| Reverse 2 | 0-13.2 | |

| Reverse 3 | 0-29.6 | |

| Dimensions(L*W*H)(mm) | 8036*2380*3240 | |

| Minimum turning radius(mm) | 6600 | |

| Wheel base(mm) | 5802 | |

| Gradeability(°) | 20 | |

| Max.traction(kN) | 65 | |

| Max.cutting depth(mm) | 500 | |

| Operating weight(kg) | 11600 | |

| Blade width(mm) | 3660 | |

| Blade height(mm) | 610 | |

| Blade rotational angle(°) | 360 | |

| Max.lifting height(mm) | 460 | |

| Blade cutting angle adjustmant Range(°) | 30-68 | |

| Min.ground clearance(mm) | 430 | |

| Working hydraulic system pressure(MPa) | 16 | |

| Brake system pressure(MPa) | 10 | |

Technical characteristics power system

Driving/Riding Environment

High-efficiency shock-absorbing seat to maximize the comfort of operation, and the operator will not be tired after long-term work The cab is equipped with air-conditioning as standard, with an integrated sealing damping system, using double-layer sealing, anti-ultraviolet glass with sound-absorbing sponge, low vibration and noise, and the noise at the driver's ear can be reduced to 85 decibels; Using intelligent display control terminal integrated instrument, online fault detection and alarm, rich display information, real-time monitoring of the entire vehicle operation, driving comfort and safety; Complete user-friendly configuration, coat hook, sun shade, radio, cigarette lighter, storage box, fire extinguisher, complete configuration, providing a richer user-friendly driving experience;Product Display

Work adaptability

It adopts the electro-hydraulic control power shift transmission produced by German ZF (ZF), which has 6 front and 3 rear gears. The best gear can be selected according to the working conditions to achieve the best combination of walking and operation; Three-stage integral drive axle, built-in imported no-spin automatic anti-skid differential, stable and reliable transmission; Balance box, up and down 15° angle swing, heavy-duty roller chain transmission, the whole machine has better passability and terrain adaptability, which can meet the normal construction work under special road conditions, the power output is stable, and the driving force is strong.Operational performance

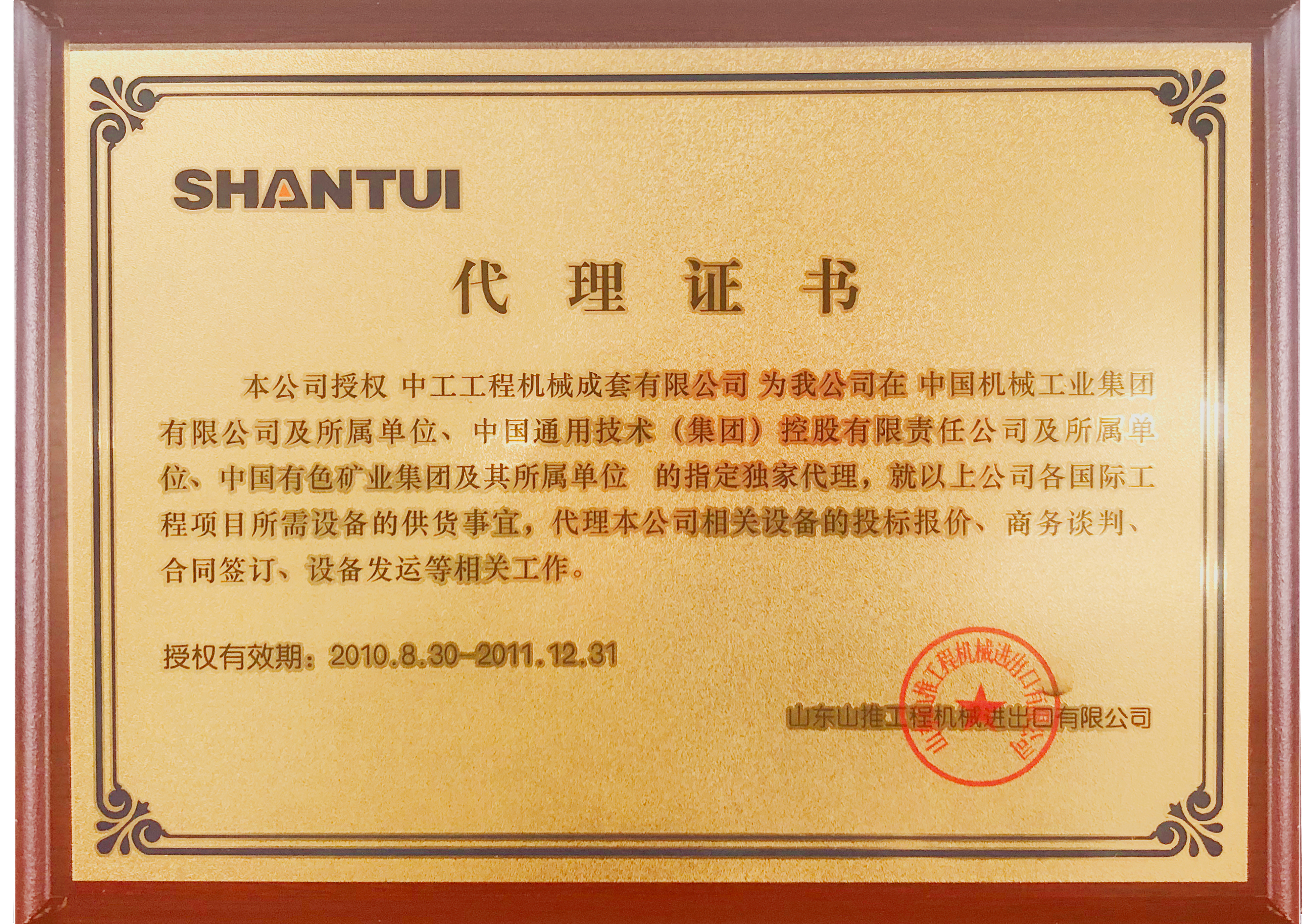

It adopts the electro-hydraulic control power shift transmission produced by German ZF (ZF), which has 6 front and 3 rear gears. The best gear can be selected according to the working conditions to achieve the best combination of walking and operation; Three-stage integral drive axle, built-in imported no-spin automatic anti-skid differential, stable and reliable transmission; Balance box, up and down 15° angle swing, heavy-duty roller chain transmission, the whole machine has better passability and terrain adaptability, which can meet the normal construction work under special road conditions, the power output is stable, and the driving force is strong.Certificate

Easy maintenance

The hydraulic pull-out cylinder only needs one person to complete the operation of the swing frame, and there is no hidden safety hazard, which is convenient for users to use; The electrical wiring harness adopts seamless corrugated pipe and line splitter to split the line, with high protection level; Maintenance-free storage battery, placed at the back of the device, has a large battery life; The core electric and hydraulic components are imported, with stable and reliable quality and extremely high reliability; Double-sided double-door large-opening hood, lubrication point lead design, daily maintenance and maintenance are at your fingertips.