Product Display

Video

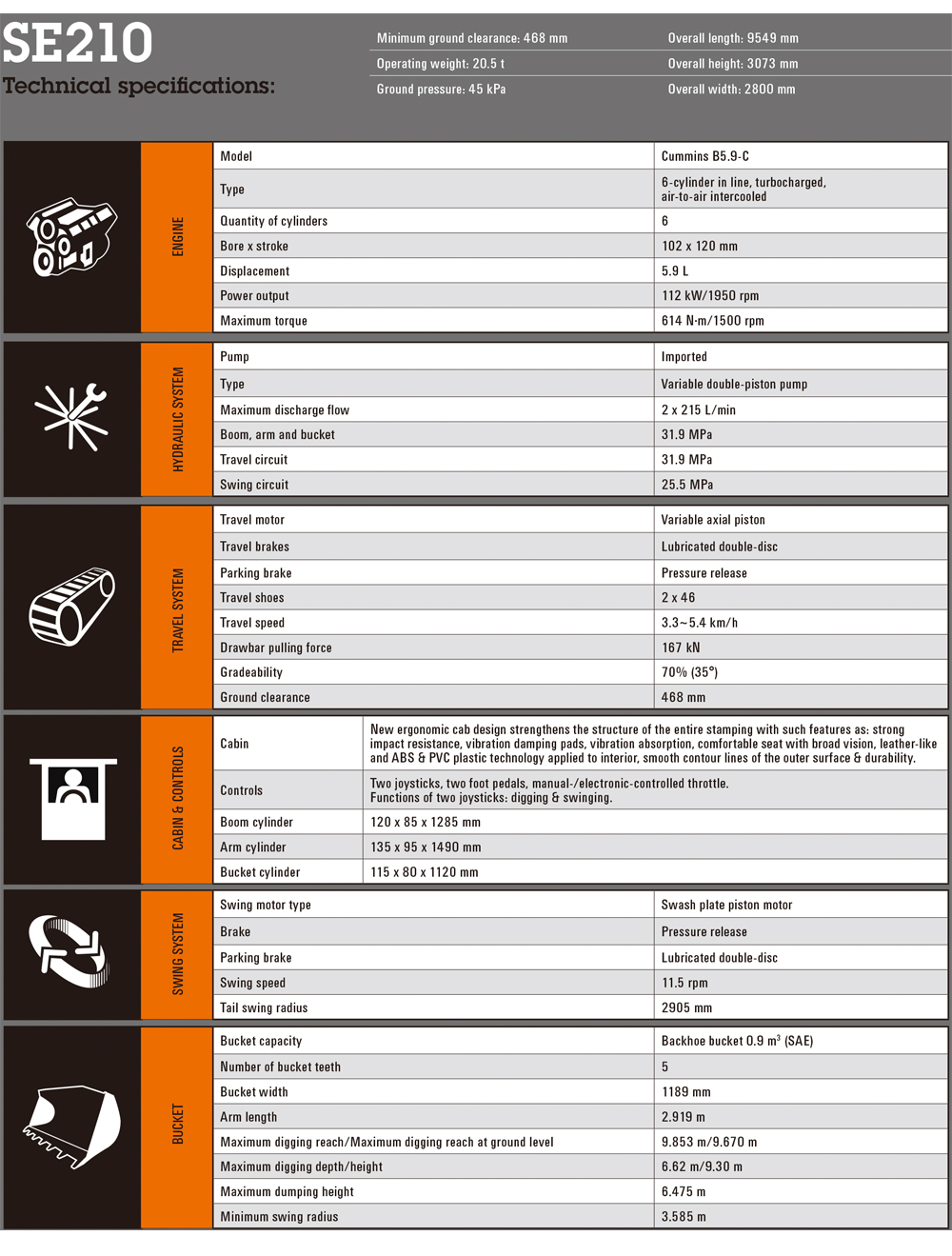

| Comparative item | SE210W (Standard version) |

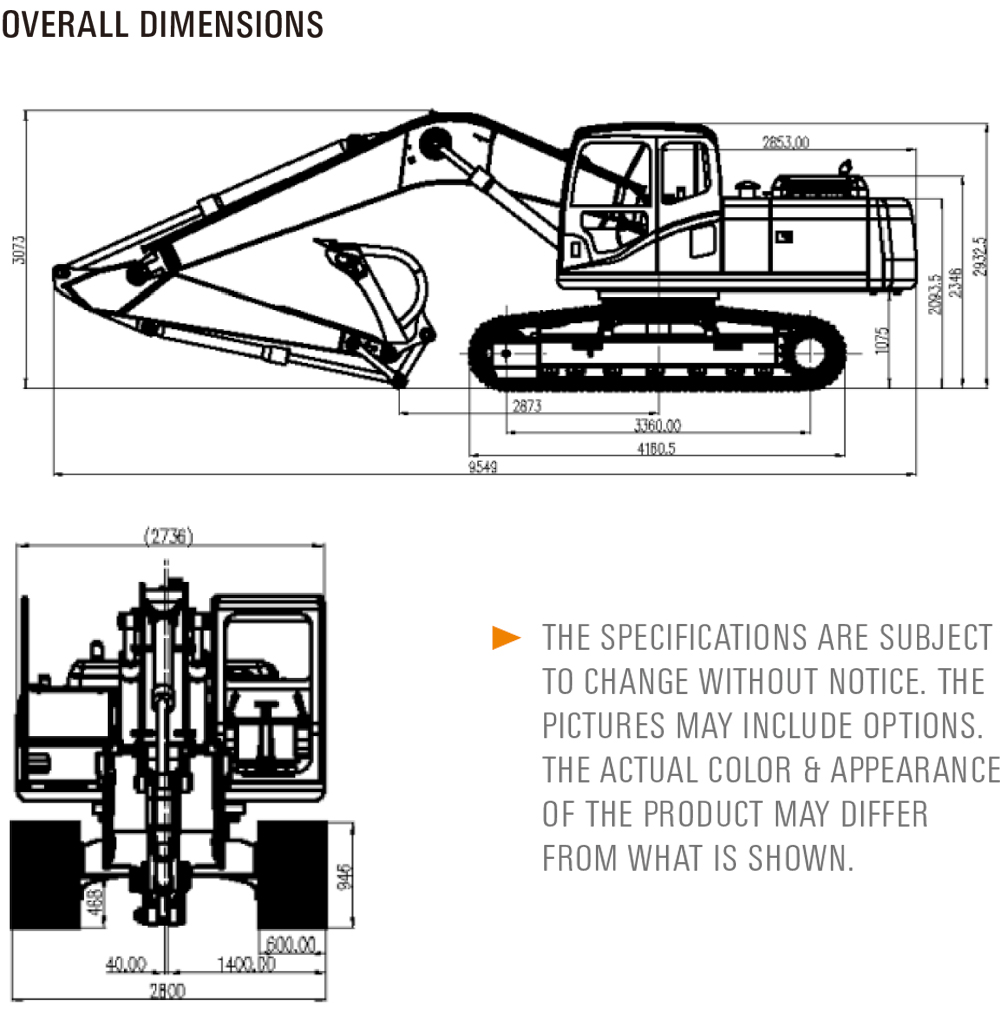

| Overall dimensions | |

| Overall length (mm) | 9543 |

| Ground length (During transport) (mm) | 4860 |

| Overall height (To the top of boom) (mm) | 3039 |

| Overall width (mm) | 2800 |

| Overall height (To top of cab) (mm) | 2977 |

| Ground clearance of counterweight (mm) | 1120 |

| Minimum ground clearance (mm) | 470 |

| Tail turning radius (mm) | 2905 |

| Track length (mm) | 4160 |

| Track gauge (mm) | 2200 |

| Track width (mm) | 2800 |

| Standard track shoe width (mm) | 600 |

| Turntable width (mm) | 2726 |

| Distance from slewing center to tail (mm) | 2853 |

| Working range | |

| Maximum digging height (mm) | 10029 |

| Maximum dumping height (mm) | 7320 |

| Maximum digging depth (mm) | 6541 |

| Maximum vertical digging depth (mm) | 5735 |

| Maximum digging distance (mm) | 9860 |

| Maximum digging distance at ground level (mm) | 9673 |

| Working device minimum turning radius (mm) | 3041 |

| Maximum lifting height of bulldozer blade (mm) | - |

| Maximum digging depth of bulldozer blade (mm) | - |

| Engine | |

| Model | Weichai WP7(China III) |

| Type | 6-cylinder, high pressure common rail, and water-cooled and turbocharged |

| Displacement (L) | 7.14 |

| Rated power (kW/rpm) | 116/2000 |

| Hydraulic system | |

| Type of hydraulic pump | Variable displacement duplex plunger pump |

| Rated working flow (L/min) | 2x218 |

| Bucket | |

| Bucket capacity (m³) | 0.9 |

| Swing system | |

| Maximum swing speed (r/min) | 11.5 |

| Brake type | Mechanically applied and pressure released |

| Digging force | |

| Bucket arm digging force (KN) | 92.5/99.5 |

| Bucket digging force (KN) | 115/124 |

| Operating weight and ground pressure | |

| Operating weight (kg) | 20500 |

| Ground pressure (kPa) | 45 |

| Traveling system | |

| Traveling motor | Axial variable displacement plunger motor |

| Traveling speed (km/h) | 3.3/5.4 |

| Traction force (KN) | 201 |

| Gradeability | 70%(35°) |

| Tank capacity | |

| Fuel tank capacity (L) | 360 |

| Cooling system (L) | 25 |

| Engine oil capacity (L) | 24 |

| Hydraulic oil tank/system capacity (L) | 250/420 |

Certificate

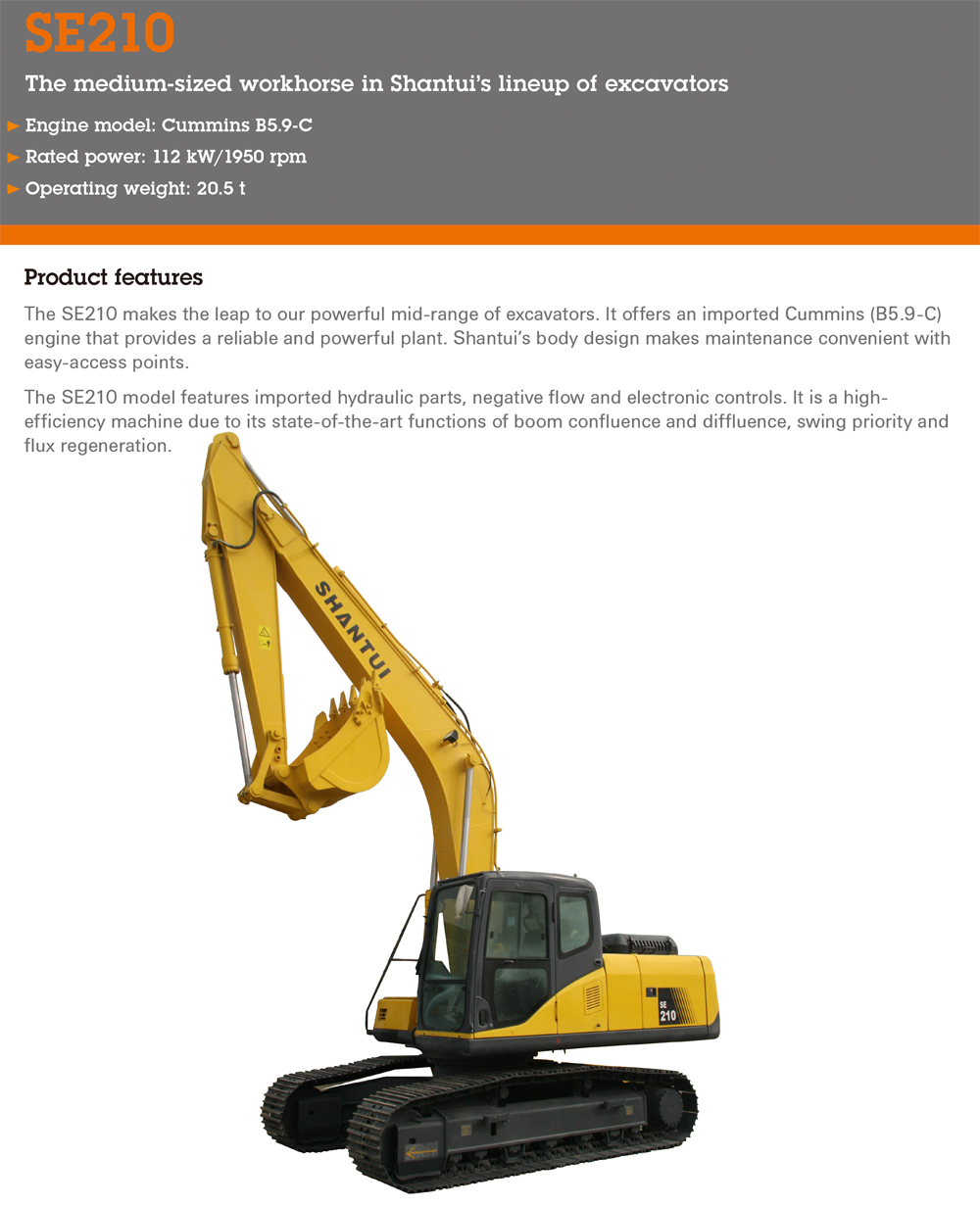

CHARACTERISTIC

Optional attachments Breaking hammer, ripper, timber grab, stone grab, quick change coupling, hydraulic tamper, quick change coupling, and breaking hammer pipeline Optional equipment of machine Refueling pump Cab warning lamp Cab ceiling lamp Cab overhead protective net Cab front upper protective net Cab front lower protective net Rubber track Narrow bucket Quick and convenient maintenances The fuel filter element, engine oil filter element, and pilot filter element are centrally arranged so that all maintenances and replacements can be completed from on same position. The high-precision fuel filter element features high water capacity and powerful fuel adaptability and the electric fuel pumping function is provided for automatic fuel refilling and easy start. With pneumatic struts, the engine hood can be opened and closed easily to realize handy opening, large opening angle, and easy maintenances and repairs. The radiator features convenient maintenances and easy accessibility. The filling of coolant and the replacement of air filter element are easily accessible to ease the checking and maintenances. The tandem radiator effectively avoids the overheating and eases the cleaning Spacious and comfortable operating environment The colors of the all-injection-molded interior trim parts are effectively matched as per ergonomics to mitigate the operator’s visual fatigue. The control devices are reasonably arranged to realize large space, broad vision, and convenient and comfortable operations. The high-power A/C system and the air cushioned seat guarantee comfortable driving/riding Intelligent electronic control and optimal power control The intelligent control system realizes high match between power system and hydraulic system to improve the working efficiency and reduce the fuel consumption. The man-machine friendly new generation intelligent electronic control system enables you to master all working status of your machine. Four preset working modes of P (Heavy-Load), E (Economic), A (Automatic), and B (Breaking Hammer) feature easy switchover Drive sprockets, idlers, track rollers, carrier rollers, and tracks 30 years of R&D and manufacturing experiences of drive sprockets, idlers, track rollers, carrier rollers, and tracks and industry’s leading technologies The mature and high-quality forging and heat treatment processes guarantee stable and reliable quality Enhanced working device The design of structural parts is comprehensive optimized and the critical load-carrying locations are reinforced to resist against severe working conditions. The baseplates, side plates, and reinforcement plates of bucket are made of high-strength wear-resistant material to improve the durability of bucket. The booms, bucket arms, and buckets of diversified specifications can be combined easily to adapt to diversified working conditions High-end system configuration The high-adaptability turbocharged engine features high torque, high altitude adaptability, and high fuel adaptability. The high-end reliable hydraulic system configuration reduces the energy loss and realizes high efficiency and energy-saving and good motion coordinationSpecification