Video

Certificate

Specification

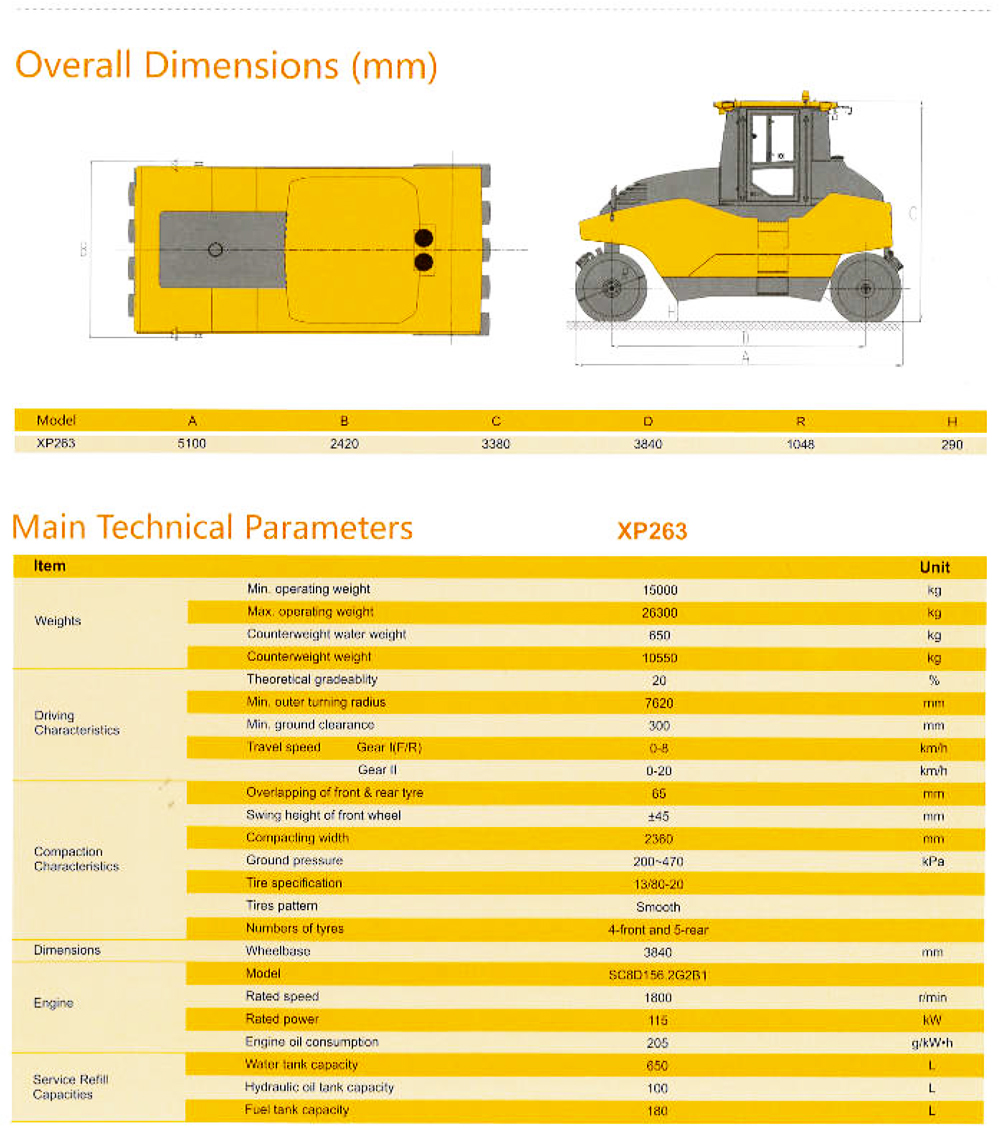

| Item | Unit | XP263 | |

| Maximum operating mass | kg | 26300 | |

| Compaction width | mm | 2360 | |

| Overlapping of tyres | mm | 65 | |

| Ground pressure | kPa | 200-470 | |

| Minimum turning radius | mm | 7620 | |

| Swing quantity of front wheel | mm | 50 | |

| Minimum ground clearance | mm | 300 | |

| Theoretical gradeability | % | 20 | |

| Wheel base | mm | 3840 | |

| Travel speed | Gear I | km/h | 0-8 |

| Gear II | km/h | 0-17 | |

| Engine | Type | - | SC7H180.2G3 |

| Rated power | kw | 132 | |

| Rated speed | r/min | 1800 | |

| Rated fuel consumption rate | g/kw.h | ≤233 | |

| Tyre specification | - | 13/80-20 | |

| Tyre tread pattern | - | Smooth tread | |

| Number of tyres | - | Front4 rear 5 | |

| Length(standard water sprinkler) | mm | 4925 | |

| Length(standard oil sprinkler) | mm | 5015 | |

| Width | mm | 2530 | |

| Height | mm | 3470 | |

| Diesel tank volume | L | 170 | |

| Water tank volume | L | 650 | |

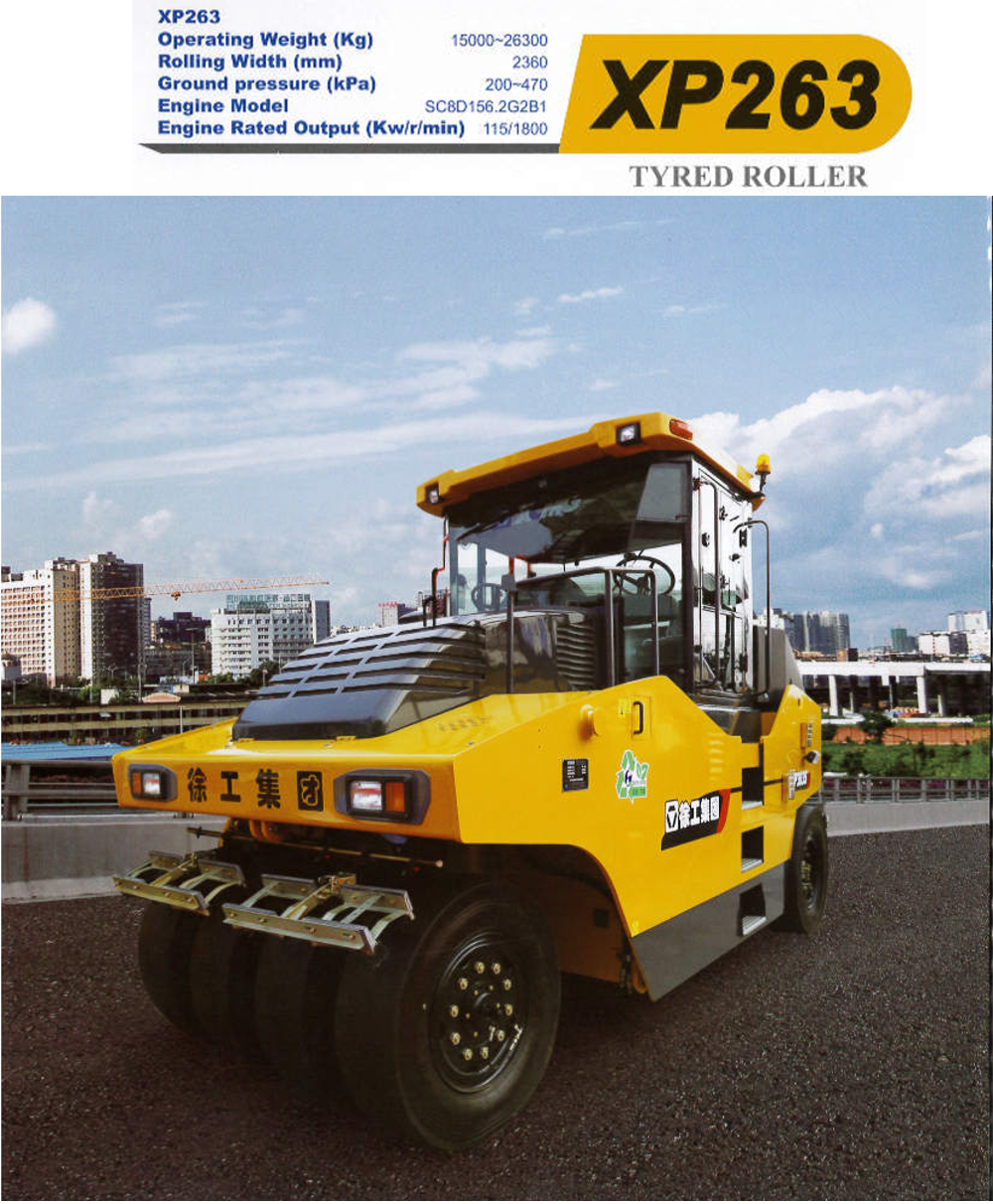

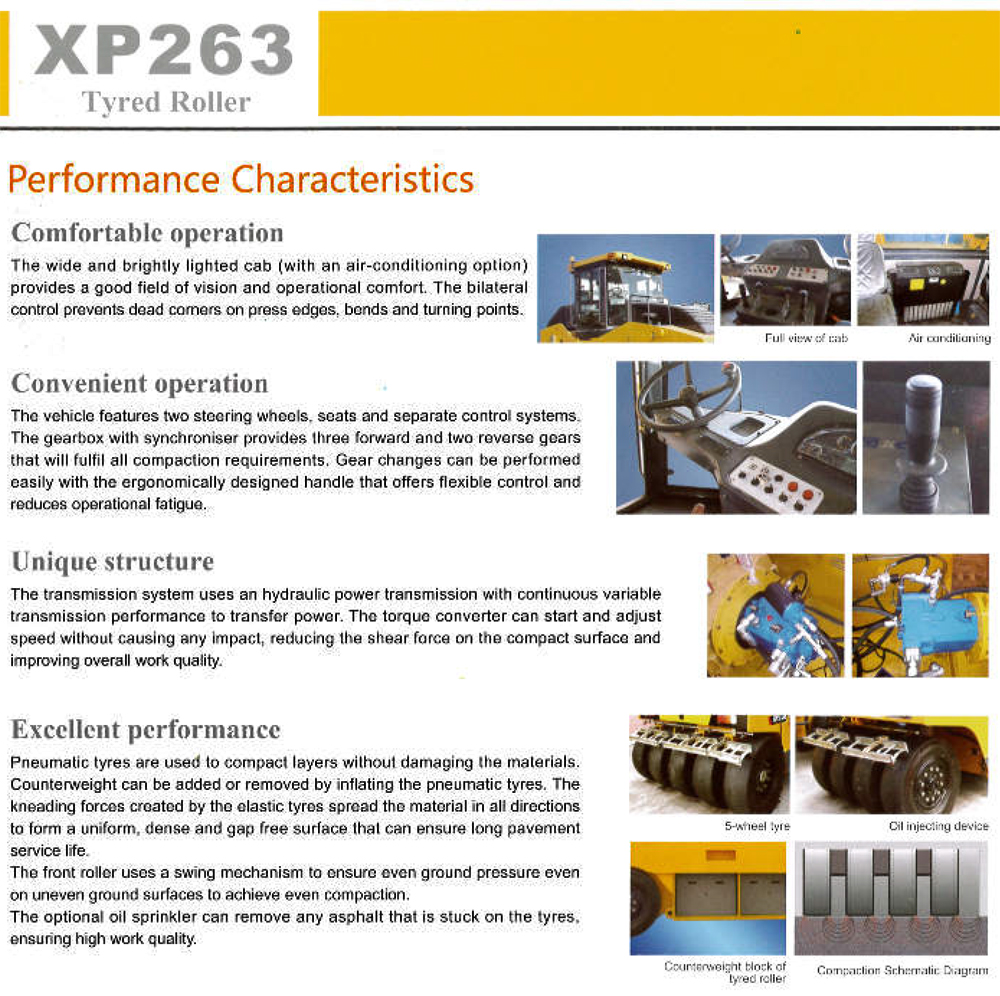

Performance Characteristics

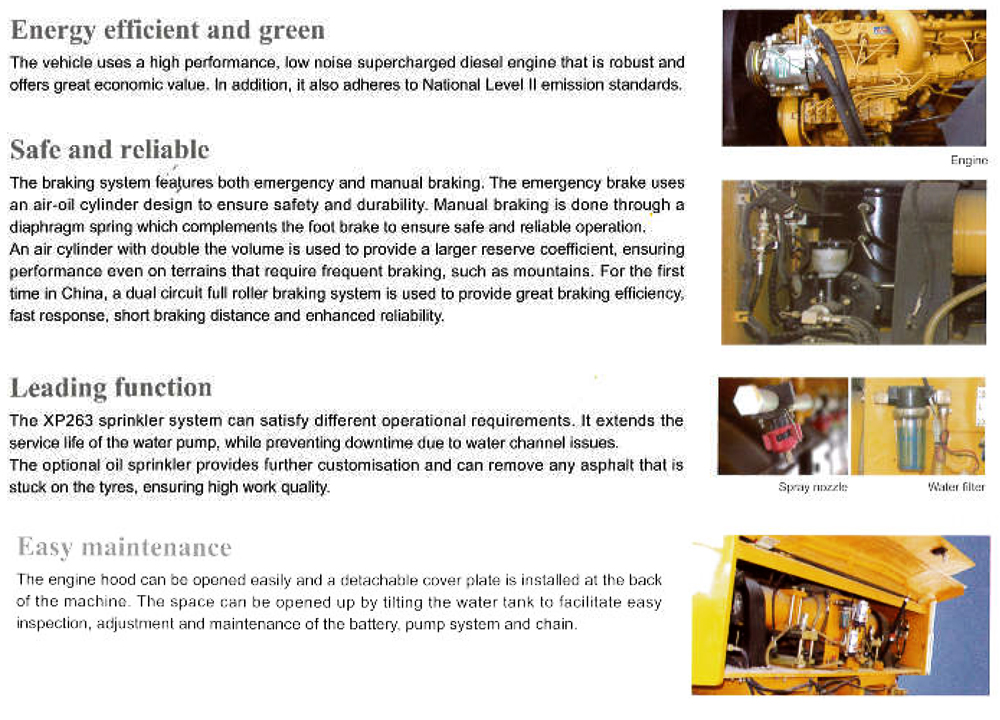

1. SC7H180.2G3 electronic control diesel engine has the advantages of high reliability, fuel economy and low noise. Its emission should meet standard in national III stage.

2. Transmission system comprises torque converter, power shift transmission, drive axle, axle, chain and rear wheel. Adopt torque converter with continuously variable transmission as well as power shift transmission, and make roller have automatic adaptability, improving transmission stability in compaction, and guarantee the diesel engine to normally work under rated condition.

3. Dual-circuit brake technology has higher brake effect, fast response speed, short brake distance and higher reliability. Guarantee safety of the whole machine, and it is particularly applicable for working in mountainous area.

4. The machine uses the box type integral frame, each part of the body is designed with access hole and overturned cover board to facilitate maintenance and curing of each component.

5. Front four and rear five tires layout is adopted. All tires are installed with scrapers for cleaning adhesive materials on the tire reads. The grounding specific pressure can be adjusted in the range of 200kPa ~ 470kPa, good compaction uniformity.